|

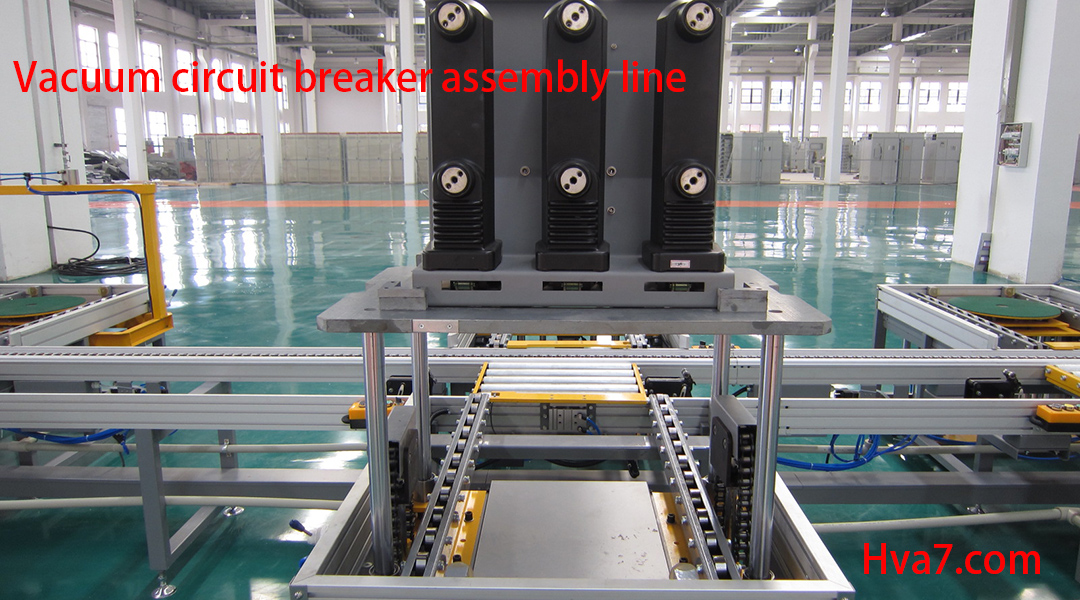

The vacuum circuit breaker production line is a specialized assembly line for manufacturing vacuum circuit breakers. Vacuum circuit breakers are high-voltage switching devices widely used for control and protection in power systems. Here is a brief description of the vacuum circuit breaker production line: Automation Level: Modern vacuum circuit breaker assembly lines utilize automated technology to achieve high-efficiency production. Production Process: The process includes material preparation, part machining, assembly, vacuum treatment, insulation testing, mechanical property testing, and performance verification.  Key Equipment: It features numerical control machines, automatic welding machines, vacuum furnaces, and high-voltage testing equipment. Quality Control: The production line has multiple quality inspection points to ensure products meet stringent quality standards. Safety Protection: Due to the involvement of high-voltage equipment, the production line enforces strict safety measures, including safety operation procedures and protective facilities. Eco-friendly Design: Environmentally friendly materials and processes are adopted to reduce the impact on the environment during production. Information Management: An information management system is used to monitor production progress and quality status in real-time. Customized Production: The production line can offer personalized production based on customer needs. Continuous Innovation: There is ongoing technological innovation and process improvement to enhance product performance and production efficiency. The efficient, safe, and environmentally friendly production of the vacuum circuit breaker production line is significant for the stable operation of the power system and the efficient use of energy.

Vacuum circuit breaker assembly line

https://hva7.com/vacuum-circuit-breaker-vcb-assembly-line/

|

|

1

鲜花 |

1

握手 |

雷人 |

路过 |

鸡蛋 |

业界动态|向阳便民网

2025-12-19

2025-12-19

2025-12-19

2025-12-19

2025-12-19

请发表评论